| - | Secondary feed-back constant current control |

| - | Self-adjustment for maximum current |

| - | 15 Weld schedules |

| - | External schedule select |

| - | Spot, twin head spot and seam welder compatibility |

| - | 3 Impulse weld schedules |

| - | Up and down slope |

| - | 9 Steppers / Linear stepper |

| - | 2 Pressure valve output and 7 operations |

| - | Current1,2,3 monitor with high/low monitor |

| - | 3 easy-to-operate counters to aid in systematic quality control and tipdressing schedules |

| - | PC and RS485 network interface |

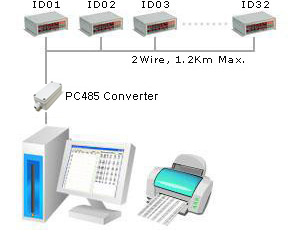

PC and RS485 Network Interface

By using welding data logger(Fcom_V2.3) software, welding data can be collected from each SK54 controller at real time and the collected data can be stored by excel file at computer.

| - | One PC can be linked to maximum 32 units of SK54. |

| - | Weld current data and schedule data can be requested to each of SK54, then the data can be seen and printed. |

| - | Weld schedule can be changed by PC. |

| - | When welding defects is occurred, event monitoring is available and time and weld current data can be checked easily at real time. |

| - | Opto-Isolated RS485 card(optional) is installed inside of SK54. |

| - | PC and SK54 is connected by 2 electric wires and the length is maximum 1.2 Km. |

Do you have any questions about the SK54?